AeroBolt™

Most people will find that many crossbow bolts perform decently well. But why is AeroBolt better than the competitor’s crossbow arrows? Why is the price of AeroBolt significantly higher?

The initial objective we had when making Aerobolt was to address the issue of the weak frontal end commonly found in high speed crossbow arrows. In 2009, we built Aerobolt I using common off-the-shelf components and while it performed well, we found that such components had concentricity issues and also had fundamental design issues. Aerobolt I was good but we knew it wasn’t great. With more time, research, testing, and the introduction of the Firenock AeroConcept System (ACS), Aerobolt II and AeroBolt III are not only built to overcome the afore issues, but with a stronger front end than ever before. We believe that Aerobolt is one of the best crossbow arrow available for today’s archers.

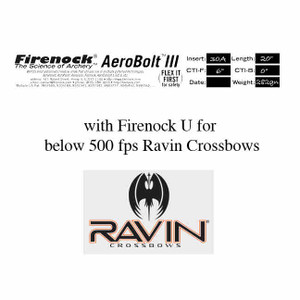

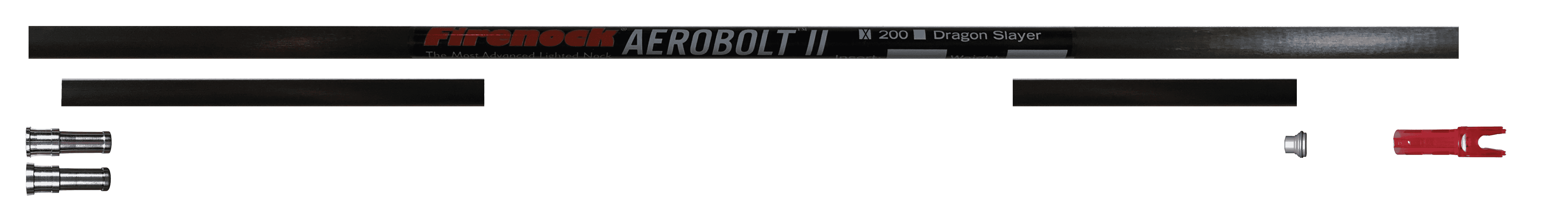

AeroBolt II-200 (AB2-200)

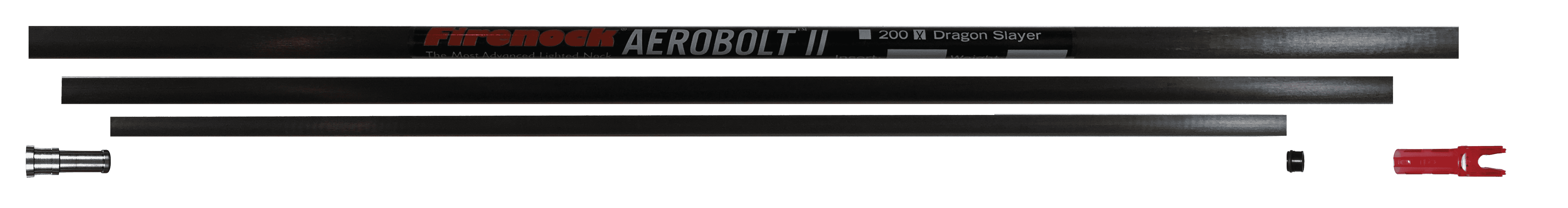

AeroBolt II-Dragon Slayer (AB2-DS)

AeroBolt II-G (ABG)

AeroBolt III-200 (AB3-200)

Harmonic Dampening

If asked for the main reason why AeroBolt Technology is so superior in performance and accuracy when compared to any other crossbow arrows, our answer would be because of its capacity for harmonic dampening. Harmonic dampening was observed when the first AeroBolt was shot in 2010. After only about five to ten feet, the oscillation of the AeroBolt stopped, which contrasted then and still contrasts with the standard minimum 15-18 yards it takes other arrows to cease oscillating. How could that be? The only difference between our AeroBolts and other crossbow arrows was our inclusion of a Carbon Inner Tube (CTI), which we (back then at least) only included to stiffen and strengthen the front end of a shaft. No archery experts could provide a definite answer. We finally received an answer after consulting material science/physics experts. We had discovered what is now the basis of our patented AeroConcept System.

Preparing the Shafts

With our discovery of the true effect of a Carbon Inner Tube (CTI), we delved into research and testing. Now, for every AeroBolt, the first thing we do is cut the main arrow shaft and its corresponding CTI according to predetermined, meticulously calculated specifications. Next, we chamfer the front end of the main shaft with our Arrow Chamfering Tool and a drill. With transport and handling, the shaft and CTI can become dirty. To start afresh, we ultrasound clean them. After, we square the CTI with our APS. We chamfer the main shaft and then square the CTI to take advantage of all the awesome design features of our AeroInsert-H. See, like most products in the Firenock line up, each insert series has grown and evolved over time. In the instance of the AeroInsert Series, we have had three generations of inserts: AeroInsert-A (AIA), AeroInsert-D (AID), and AeroInsert-H (AIH) respectively. AIA boasts Self-Concentric Technology while AID, now discontinued, boasted Double Shoulder Technology. AIH unites and takes advantage of the technologies from both prior inserts. And, due especially to that double shoulder, we can then mate the Carbon Inner Tube with our AIH perfectly using our twopart epoxy, AGUSSE. And that’s the final step of our preparation process.

Building the Complete System

At the end of the standard preparation process we should have two* raw components: the chamfered main shaft as well as the CTI & AeroInsert-H. These next steps are where our production process truly shines. After joining the CTI and AeroInsert-H pairing to the main shaft via vacuum pumping, we take multiple measures of quality control. All in all, we believe in providing our customers with the best, money and time aside. Therefore, we sort our arrows after building them. For although we do vacuum pump our completed insert(s) into the main shaft to assist in efficient gluing, we know that there is still variance. To overcome this, we weigh, hand label, and sort every shaft to a grain.

Completing the AeroBolt

Now with a weight-labeled, ACS equipped shaft, we begin the last steps of building an AeroBolt. Though before we claimed that its capacity to harmonically dampen was its most significant feature, there is arguably another significant feature about all our AeroBolts—they all are first dynamic bend indexed with our PAPS before fletching. After this, of course, we do fletch Aerovanes according to that index with our Aerovane Jig. Finally, we square the nock end of the completed AeroBolt one last time.

Additional Notes

All AeroBolt** are optimized for the Firenock lighted nock system, fletched with Aerovane II or Aerovane III vanes, and equipped with an AeroConcept System compatible AeroInsert-H. Our standard vane configuration is three vanes, respectively, in white, yellow, and red. Custom vane configurations (zero, two, or four) as well as custom color combinations are also available but with extra charge. All Aerovanes on AeroBolt are fletched with the Firenock Aerovane Jig and glued on AG0600. AeroInserts are available in aluminum (~17 grain) or stainless steel (~50 grain). Lastly, note that you can order and re-order your AeroBolts in specific weights and lengths.

*As of 2018, like seen in the diagram for AB2-200, there is an option to add another Carbon Inner Tube at the back of the arrow. This addition is the AeroConcept System 2.0 and increases the total of raw components to three instead of two. For clarification, Dragon Slayer always has three raw components but cannot be equipped with the ACS.

**While all AeroBolt II also comes with an AeroPoint option, AeroBolt III does not match the price.