Broadheads

Currently, there are three Firenock serieses of broadheads: Traumahawk, Dagger, and SwingBlade. Each covers different use cases as well as materials and sizes. For 2020, the Dagger series recieved six new additions while for 2021, the SwingBlade series adopted the Stalker AeroStem technology designed to suit ultra-slim or 0.166" ID size arrows.

Traumahawk

Utilizing blunt force trauma, the Traumahawk is our invulnerable broadhead developed especially for high speed crossbows. Designed to work a bit like the Native American's lethal weapon, the tomahawk, this broadhead transfers the maximum amount of kinetic energy in the initial or first contact of an arrow to the game.

Dagger

Using compound single bevels, the Dagger's geometry provides rotation not only during initial contact with the game but all the way though the animal. This specific rotation results in cavitation within a high oxygen-enriched organ, such as a lung, and forces animals to expire quickly. The upgrade to using Metal Injection Molding (MIM) during the manufacturing process only perfected the effectiveness of this broadhead.

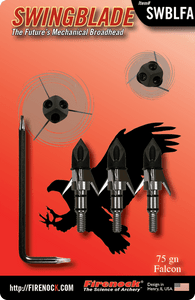

SwingBlade

As its name implies, SwingBlade's three blades deploy by swinging out from their clasped position on and only on impact (US Patent # 9,803,963). This design allows it be used on high speed projectiles due to a minimum crosswind signature during flight (~3/4"). It is also a completely customizable interchangable series, boasting four unqiue blades as of 2021.

Consider the summaries below for assistance in your purchase decisions. Note that more details can be found about each product line on their own respective webpages.

Introduction

After the launch of Aerovane in 2007, we kept hearing that broadheads did not fly well with it. This is because Aerovane is airfoil-based, meaning that the faster the arrow flies, the faster it will spin due to circular lift. And as the speed of archery projectiles bas only continued to get faster, broadhead technology hasn’t held up. Whether projectiles are fletched with Aerovane or not, a higher degree of aerodynamic efficiency in broadheads was necessary.

The Traumahawk

Traumahawk, as the first and only blunt force trauma broadhead available on the market, has an edge instead of a point. If one looks closely, the front of the Traumahawk is an exact replica of a large drill bit tip. This design is meant to harness the excessive force that a modern crossbow gives out. According to our research, it only takes about 25lb KE for an arrow with a well-designed broadhead to pass through a typical full-grown North American white-tailed deer. Today’s high speed, high power crossbow however, easily exerts more than 130lb KE, over four times more power than required!

With so much extra energy being wasted, we wanted to develop a broadhead that would transfer as much of it as possible. That broadhead is Traumahawk. Traumahawk efficiently transfers ~90lb KE to a target in the same conditions as stated earlier. Note, however, that Traumahawk is meant to be equipped on high speed, high power projectiles. The only exception is use as a small game head for recurve.

The Dagger Series

After the launch of Traumahawk, we received several customer requests to create a similar broadhead but with less use restrictions. The answer was Dagger. While we wanted to maintain its high energy efficiency, Traumahawk’s initial edge required too high of a minimum speed and power. So we compromised with a point and added another, smaller bevel. This multi or compound single bevel design requires less energy to penetrate while still being a solid, one-piece design. The majority of its weight remains on the outer perimeter and still encourags gyro spinning.

The Phenomenon of Cavitation

During testing for Traumahawk, something very unusual happened. After a closer look at the game harvested from Traumahawk, we noticed some sort of pink foam had collected around the impact sight. With some research, we learned what we had stumbled upon: cavitation.

Cavitation is the interesting natural occurrence of small vapor-filled cavities (bubbles) wherever there is rapid changes in pressure. This pressure change occurs because of Traumahawk’s dual cavities. While we originally added them to keep the weight of the broadhead on the outside, at high speeds, these cavities also form low pressure zones.

With the opportunity to further adjust and perfect the Dagger’s design due to Metal Injection Molding (MIM), we decided to add rounded, airfoil like edges to the inside of its same dual cavities. This unique and patent-pending design takes advantage of our broadheads' high rotation, high energy efficiency and optimizes it for the cavitation process, especially when used in tandem with Aerovane II/III. Now, when the MIM Daggers pass through game, cavitation will force oxygen to be released from the blood, and foam is formed. Animals will expired quickly as normal breathing becomes extremely hard, if not impossible. Game will drop within sight, making blood trails moot.

The SwingBlade Series

SwingBlade was actually originally designed because we were given a challenge: a broadhead that could fly [1] on an Aerovane III fletched shaft, [2] in 35mph plus crosswinds, [3] at 550fps, [4] without the need to broadhead tune, and [5] with accuracy. It seemed an impossible task. Traumahawk and Dagger already checked four of the five requirements, but a broadhead that didn’t need practice? It was unheard of! You can’t just screw your field point off your arrow before a hunt, install a broadhead, and then expect success! At least, not until SwingBlade.

SwingBlade, being a mechanical broadhead, still has a legal cutting diameter of ~3/4” when closed. Unlike other mechanical broadheads however, the three blades operate independently. Each blade has two single bevel grind surfaces, one on its front and one on its back. This design ensures that the blades will only engage from behind their O-ring when it makes contact with the target. That way, during flight, SwingBlade will behave just like a field point.

Note that the two newer, larger SwingBlade blades, Talon and Saber, still meet the above requirements but with speed limitations i.e. archery projectiles should not exceed 315fps for Talon or 300fps for Saber.

The Stalker SwingBlades

In January of 2021, Firenock was issued our 41st US patent on a new insert that uses a stem system that offered an alternative to AeroOutsert for 0.166” ID size shaft. Utilizing AeroStem Technology and one of the two new Stalker SwingBlade bodies (in stainless steel or aluminum), you can take full advantage of SwingBlade.